SuperFAST 46" Utility Press Pad For Sankosha

| {{resource("/Shared/Label/QuantityTable/Qty")}} |

{{volumePrice.Quantity}}+ {{resource("/Shared/Label/QuantityTable/Each")}}

{{volumePrice.Quantity}}+

|

|---|---|

| {{resource("/Shared/Label/QuantityTable/Price")}} | ${{volumePrice.Price.Amount | toDisplayFormat}} |

| {{resource("/Shared/Label/QuantityTable/Save")}} |

—

{{volumePrice.Save | toDisplayFormat}}%

|

{{format(resource('/ProductPage/Labels/SoldInIncrementOf'),displayVariant.SoldInIncrements)}}

{{format(resource("/ProductPage/Labels/MinimumOrderQuantity"),displayVariant.MinimumOrderQuantity)}}

Superfast Press Pads Are Optimized For Your Operation.

Steams In Six Seconds

SUPERFAST Press Pads steam up super-fast—they’re ready to go in just six seconds!

Secure Fit

A self-locking closure ensures a snug, secure fit on your pressing machine.

Breathable Layers

Each layer of our SUPERFAST Press Pads is constructed with porous materials for optimal steam flow.

Four Layers Built To Breathe.

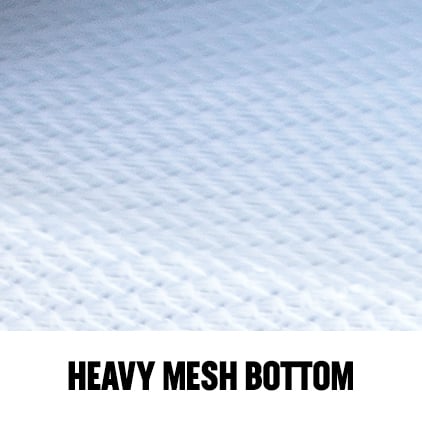

Each layer of our SUPERFAST Press Pads is constructed with porous materials for optimal steam flow inside and out. The outer layer consists of a breathable shell, followed by a thick resilient foam layer that adds cushion and insulation to absorb impressions from pockets, buttons, and zippers. Next, a heavy flannel layer holds moisture to prevent the pad from drying up and cracking. To round it all out, a thick mesh base allows for quick steam flow through the bottom of the press pad. All together, these allow steam to flow better and vacuum faster—helping to increase your pressers’ production rate per hour.